In daily applications such as household drinking water, industrial water, wastewater treatment, agricultural irrigation, and municipal river water treatment, UV sterilizers play a crucial role. So, how can you choose a high-quality UV sterilizer?

First, check the key specifications. Prioritize UVC lamps with a wavelength of 253.7nm. If the water has odors, a dual-wavelength UV lamp (253.7nm + 185nm) is recommended, as this combination is most effective at breaking down the DNA or RNA of microorganisms and removing odors. Choose the appropriate lamp power and UV dose based on water temperature, clarity, and flow rate.

Second, verify international certifications. Ensure the product complies with CE (EU), ROHS (UK), FCC (USA), EPA (USA), and EPR (Germany) standards to guarantee quality and safety.

Third, consider the lamp type and lifespan. There are currently three main types of UV lamps used in water treatment:

1. UV LED Chips – These are electronic components rather than lamps. They are mercury-free and environmentally friendly with long lifespans (up to 10,000 hours). However, they have very low power and UV output, limited sterilization distance, narrow effective range, and a beam angle of only 60°, with intensity sharply decreasing away from the center.

2. Low-Pressure Mercury Lamps – These are widely used in UV sterilization. They offer long lifespans: standard models average 5,000 hours, while Lightbest low-pressure mercury lamps reach up to 9,000 hours. Lightbest also produces amalgam lamps using advanced amalgam technology with lifespans of up to 16,000 hours—surpassing UV LED. They come in a wide range of power options (1W–1000W), deliver high UV doses, have broad sterilization coverage, and ozone-generating models can provide 360° sterilization. The downside is the presence of mercury, requiring careful handling.

3. Medium-Pressure Mercury Lamps – These are suitable for industrial-scale, high-flow applications. Power ranges from 1,000W to 20,000W, offering high sterilization rates and large treatment volumes. However, they are more expensive and have shorter lifespans than low-pressure lamps.

Next, consider the material of the UV sterilizer. SS304 stainless steel is commonly used. For food-grade or higher-level applications, SS316 is recommended. For corrosive water sources or seawater desalination, UPVC or PE materials may be more suitable.

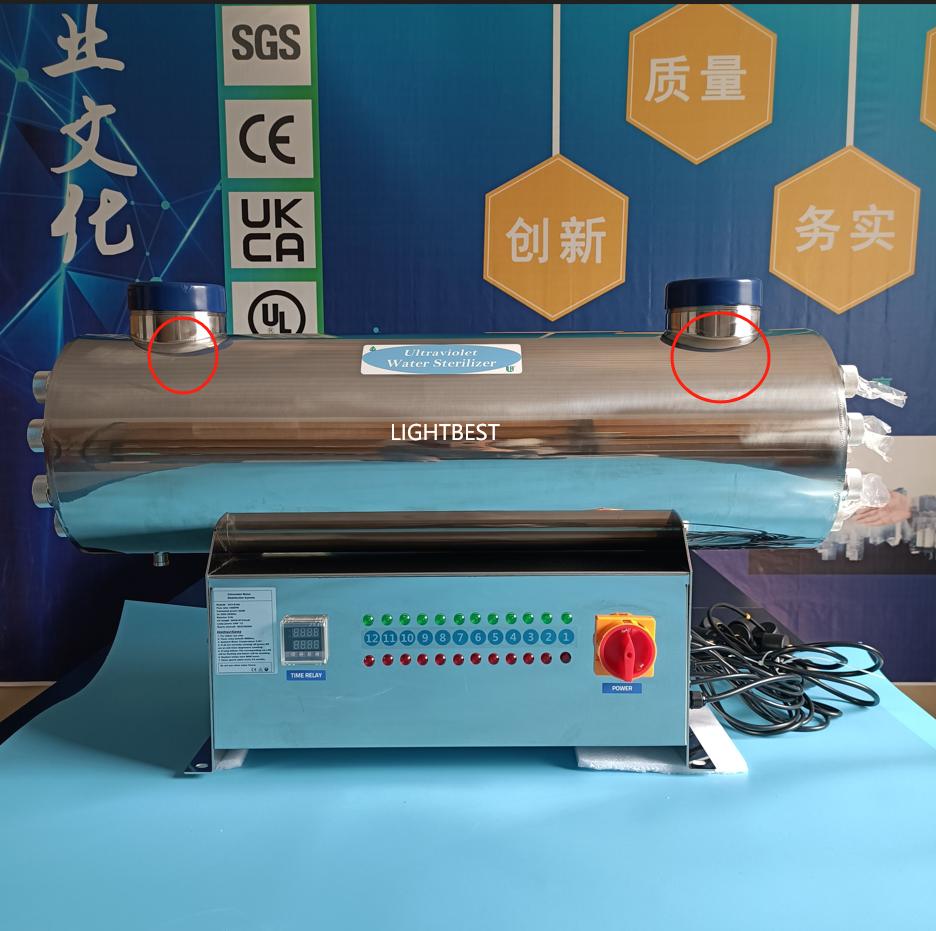

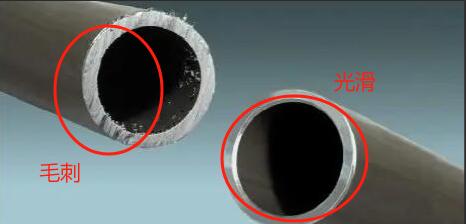

Finally, evaluate the manufacturing quality. Poor-quality UV sterilizers often have substandard welding that can leak over time. Inferior models may rust internally, lack passivation, polishing, or ultrasonic cleaning, and have rough inner chambers. In contrast, high-quality sterilizers like those from the Lightbest brand feature seamless, smooth welding, passivated and polished surfaces, and ultrasonic cleaning. Both the interior and exterior are polished for enhanced UV reflectivity and minimized dead zones. Lightbest standard stainless steel UV sterilizers use 2.5mm thick stainless steel, can withstand pressures up to 6 bar, and support customization of both shell thickness and control cabinets.

(Inferior welding)

(High-quality welding)

Post time:2025-06-30 11:08:34